Summary

Car seats are made up of 3 major components: a frame for support, foam for comfort, and a trim cover for appearance. The actual building of the seat follows in the same order. The frame is made of fabricated metal components and assembled. Then, the appropriately designed foam is molded in a foam plant and the trim cover is sewn together in a trim plant. Most foam is produced close to the final seat assembly plant, and most trim covers are produced in plants located in Mexico. Once the frame, foam, and trim covers are produced, they are shipped to the “Just in Time” seat assembly plants (JIT Plant) to be fully assembled. These JIT plants are very close to the vehicle assembly plants so the seats are installed in the vehicle shortly after they are assembled.

Where does YKK fit in to all of this?

In general, most of YKK® automotive products are used to attach the trim cover to the foam and close out the seat when it is assembled. Regarding YKK’s tie-down products, we offer QUICKFIT® fastener and EZ-CLIP® fastening clip. Our products offered for seat close out are our 5CH CONCEAL® zipper, 5CI conventional zipper, and ERGO-J® sheet fastener.

QUICKFIT®

QUICKFIT® fastener, and its counterpart QUICKLOOP® fastener, is a hook to loop fastener used to attach the trim to the foam of a seat. QUICKLOOP® fastener is sewn to the trim cover of a seat, and QUICKFIT® fastener is molded into the trenches of the foam while it is being produced. During seat assembly, the seams of the trim cover are placed in the trenches of the foam and produce the lines you see in a seat.

EZ-CLIP®

EZ-CLIP® fastening clip is another tie-down system that consists of a suspender and clip that is sewn into a trim cover. The suspender itself is attached to the trim cover and has clips attached to the other side of the suspender. The clips then attach to wires that are molded into the foam. These wires are in the trenches of the molded foam, and when the trim is attached to the wires via EZ-CLIP® fastening clip, it also produces the lines you see in a seat.

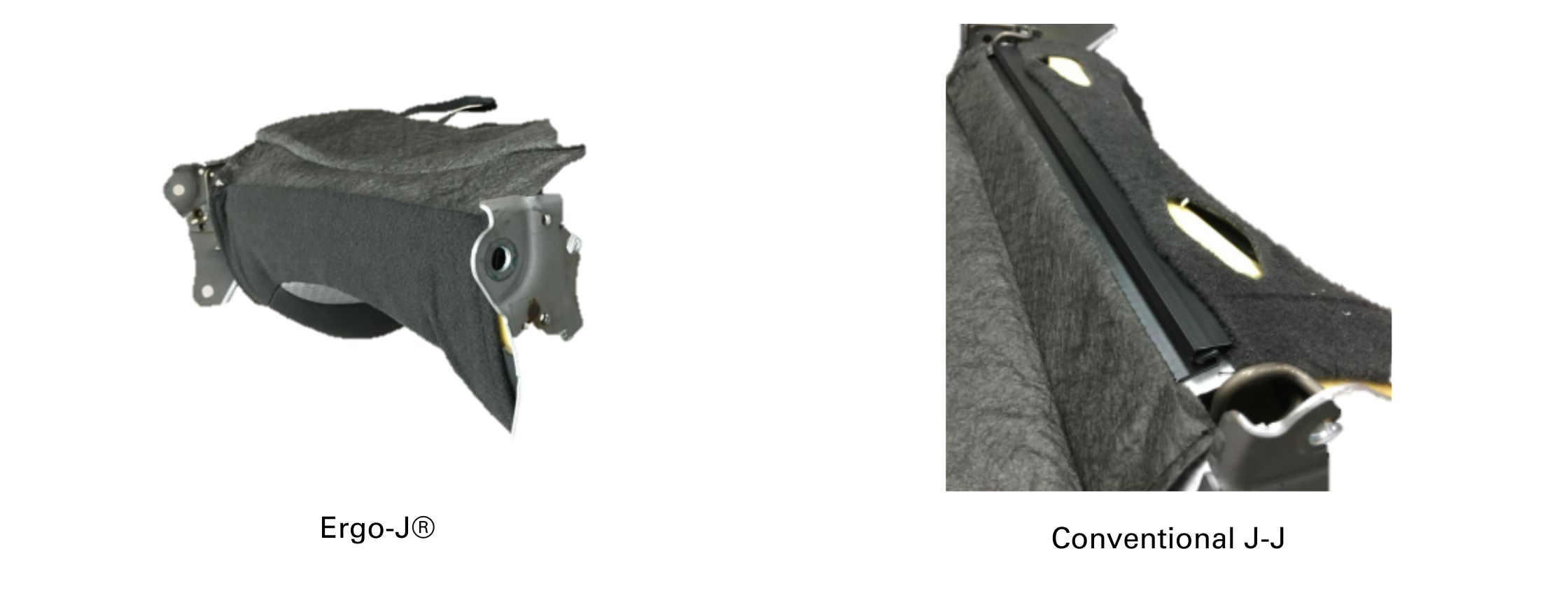

ERGO-J® sheet fastener is YKK’s version of a J-Retainer. J-Retainers are typically used in the process of seat close out. One would normally see them at the bottom of a seat that connect the front surface of a trim cover to the back. ERGO-J® sheet fastener is special because it is designed to make the process of seat close out much easier and a lot less strenuous on the operator. This special design also has appearance benefits and makes it much stronger.

CONCEAL® and conventional zippers

Both of YKK® automotive zippers are coil zippers and serve essentially the same purpose. When the trim cover is completely attached to the foam and covering the seat, the last step in completing the seat is the close out of the trim. Both the CONCEAL® and conventional zippers allow for an operator to bring two pieces of the trim cover together and close the seat. The difference between these two zippers is in their appearance. The conventional zipper is just like a zipper you would see on an article of clothing but is much stronger in comparison to these zippers. The CONCEAL® zipper essentially conceals the actual coil and teeth of the zipper by pulling the two pieces of trim together and over itself, making it appear as a sewing seam. It too is much stronger than a zipper on an article of clothing.

Check out some additional YKK innovations for the automotive industry on YouTube:

Learn more about YKK’s products for the automotive industry by visiting our Digital Showroom or contact us!

YKK, QUICKFIT, QUICKLOOP, EZ-CLIP, CONCEAL and ERGO-J are registered trademarks of YKK CORPORATION.

©2022 YKK Corporation of America