We are the undisputed leader in quality fastening products and assemblies. Your manufacturing quality expectations are exceeded. You have a supply chain partner that performs highly on supplier ratings and regulatory requirements while working with you to optimize continuous improvement objectives.

Medical Devices

Helping to heal

why choose ykk?

Unparalleled quality

Productive relationships

We listen to you and make every interaction count. Your needs are heard and prioritized in order to meet your objectives on your timeframe. You rely on us as trusted technical advisors and engaged partners to provide high-value technical support that delivers the best solution for your needs.

Lowest total cost

We tailor our products and services to achieve comprehensive cost reductions. You reduce costs in ways you didn’t expect and stay ahead of reimbursement cuts. You challenge us to find creative ways to reduce price, increase your efficiency, reduce your waste and shrink your environmental impact.

Innovative Solutions

We solve difficult problems and exceed goals. You have a partner who thinks out of the box and meets your larger needs. You get better solutions to bigger problems from a partner who understands the process from engineering design to the production floor, who has flexibility to manufacture products or assemblies – or to provide you with your own custom machinery, and who will simplify sourcing by offering a full suite of products and services.

Life Cycle Management

We excel from commercialization to high-volume. You get speed, quality and cost-effectiveness from product development and launch, through acceleration and on to high-volume, low-cost manufacture. You have a supplier partner who manages all aspects of the product life cycle, meeting your objectives at every point.

Sustaining Communities

We give back to society and provide for the future. You have a supplier who matches your values and commitments to environmental regulations, ethical sourcing and community support. You have confidence that they invest in both today’s and tomorrow’s workforce in order to maintain your robust supply chain. You can rely on them because they are the preferred employer in the communities they serve.

YKK Offers an extensive Fastening Product Line to meet any medical application

Medical wearables technology has advanced significantly in recent years. Fasteners play a critical role in product performance. With their unique perspective and capabilities, suppliers are ideal resources to help medical device manufacturers innovate, drive competitiveness, and enhance profitability. But innovation can go even further when manufacturers align themselves with suppliers that bring a new level of insight that can only result from the formation of trusting, intimate relationships with their customers.

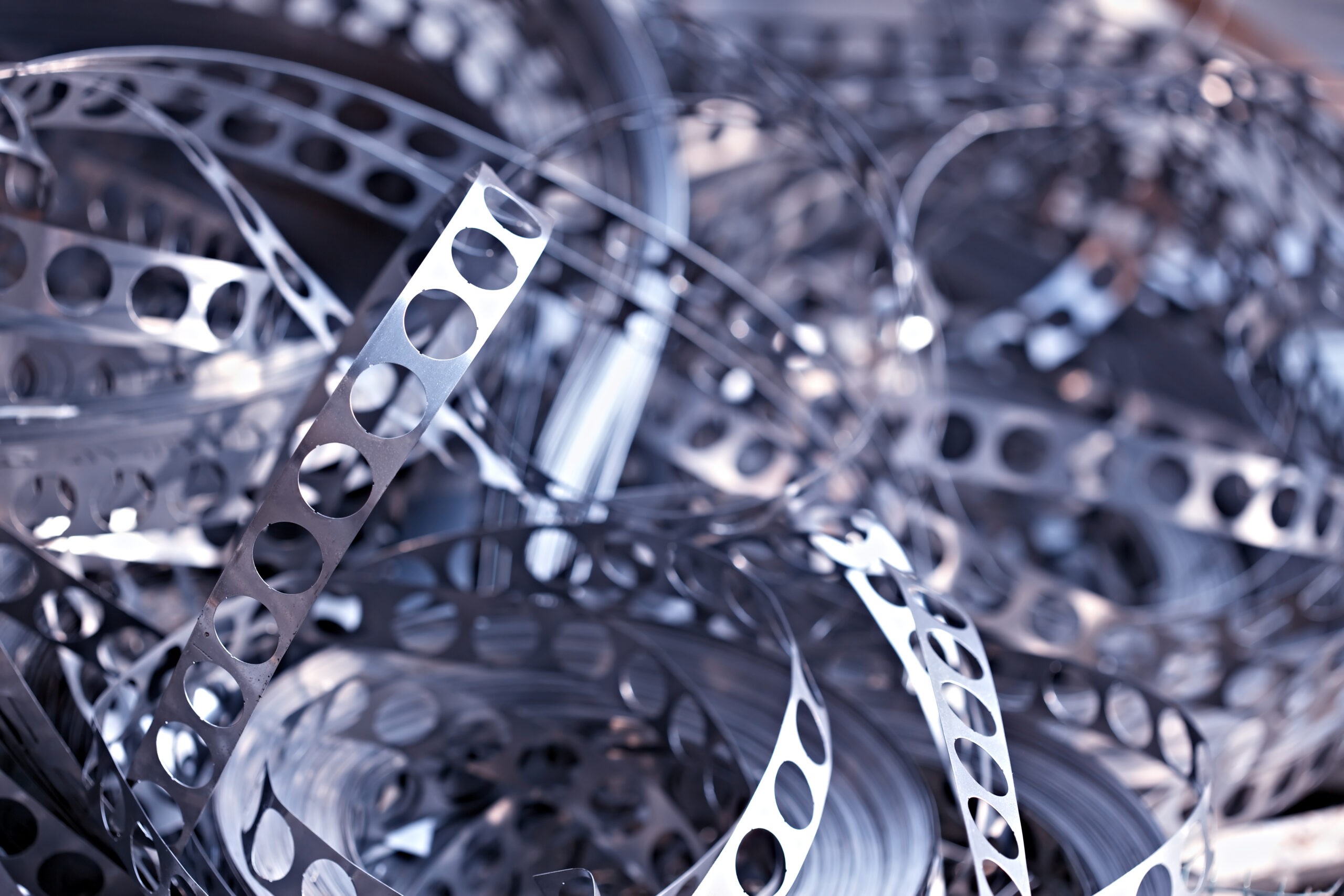

progressive stamping

YKK has specialized in metal stamping and forming for over 125 years. We offer a large range of press capabilities, tight tolerance, variety of substrates and thickness, plus in house design to meet specialized customer needs.

weaving

Our Tape Craft plant produces high quality and cost effective webbings for multiple applications such as patient handling and orthopedic slings. Our range of off the shelf and tailored webbings can meet the most stringent strength and quality requirements.

extrusion

YKK® plastic extrusion products focus on delivering high performance. Our extruded hook fasteners meet the specification of numerous applications. Products can be tailored to meet new requirements and are available in a multitude of profiles and resins.

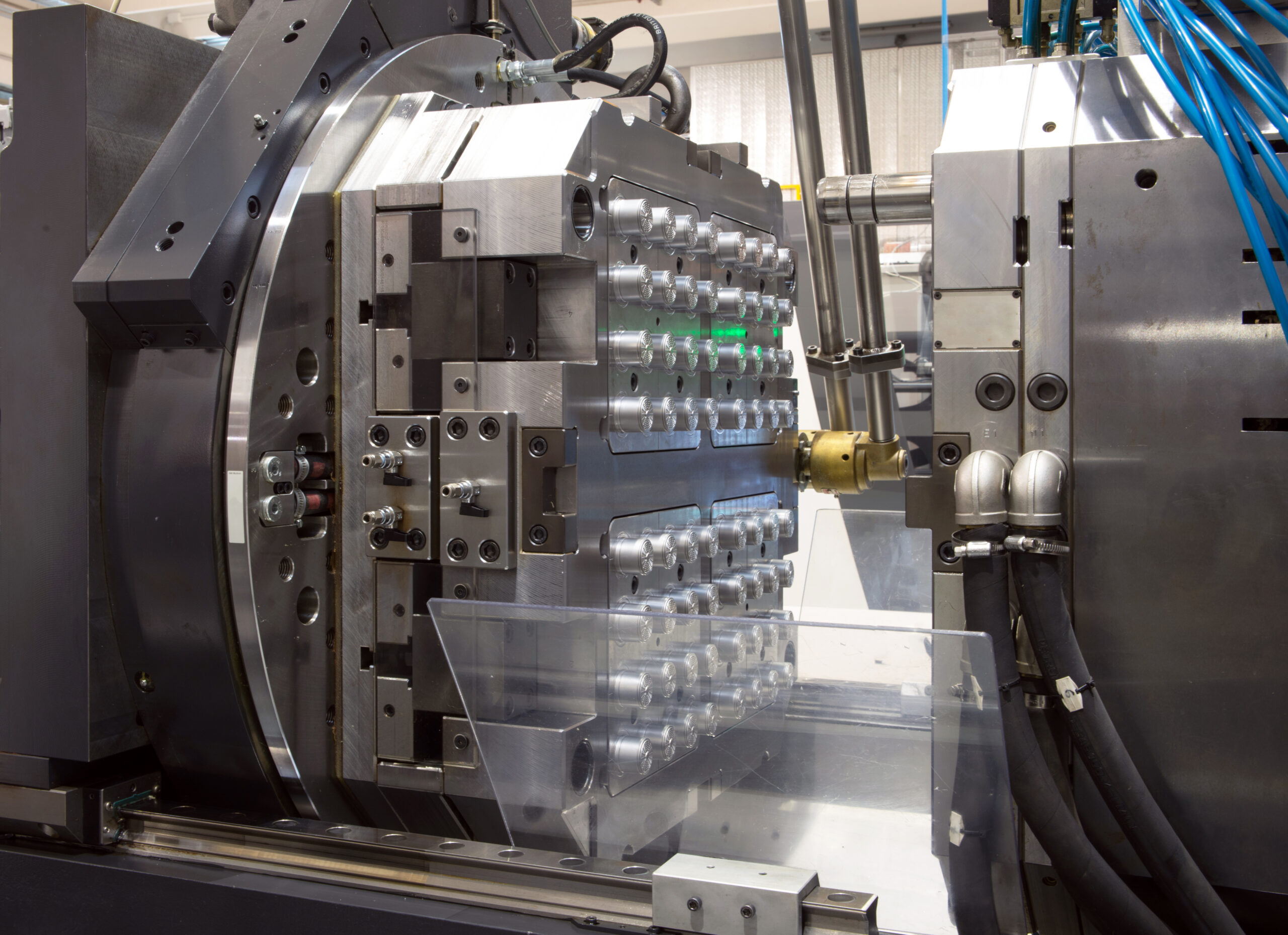

injection molding

YKK offerings extend far beyond our wide range of catalog parts. For custom applications, we offer expertise in product design, material selection and cost management to develop injection molded products that meet their performance and price requirements.

fabrication

Drawing on our extensive product line and capabilities, YKK is able to provide a full range of fabricated components & custom assemblies to drive out operational and opportunity costs and rationalize the supplier base.

die casting

YKK’s die casting process allows for customization of our Slide Fastener and Snap and Button products to meet Industry regulations and customer performance requirements. We have in house design and tooling capabilities to meet our customers needs.

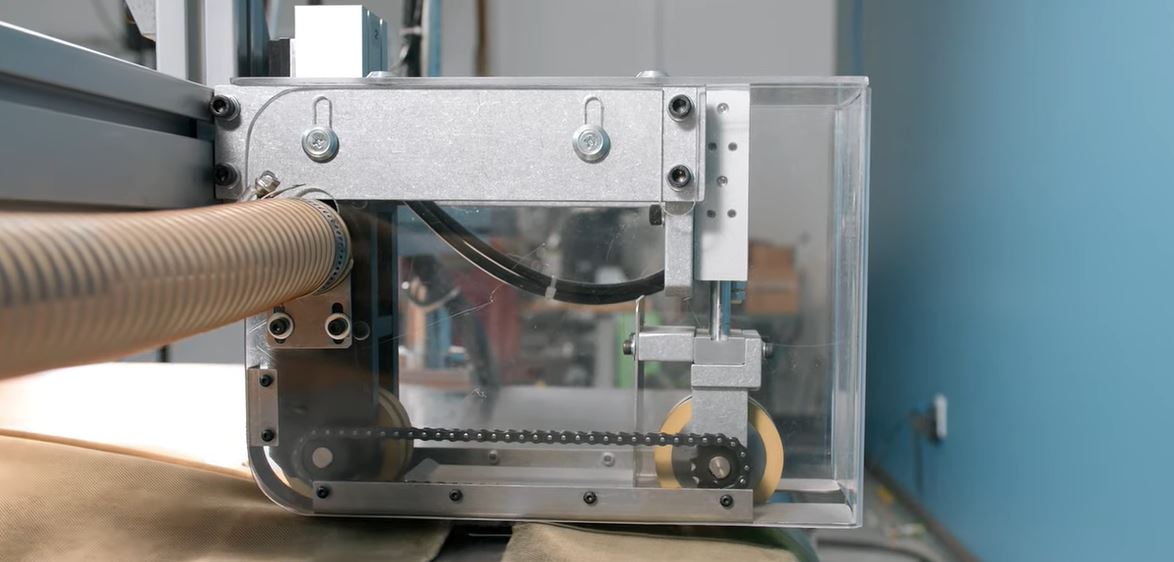

machinery

Our Solutions group delivers process improvements, labor savings, improved quality & deskilled operations. We develop methods and machinery for customers to integrate our Fastening products into their finished products.

Articles about YKK’s Medical Device Solutions

3 Pitfalls to Avoid When Choosing Fasteners for Wearables

Medical wearables technology has advanced significantly in recent years. Fasteners play a critical role in product performance. In this article for Medical Design & Outsourcing, Keith Glaser, Director – Industrial Fastening Group at YKK USA, explores three key pitfalls to avoid when choosing fasteners that can result in underperforming wearables, wasted time and money and missed opportunities for innovation.

Prioritizing Total Cost of Ownership During New Product Development

Total Cost of Ownership (TCO) calculates all costs associated with a particular product or service through its entire lifecycle. It considers price, risk, opportunity cost as well as hidden costs, including product recalls. In this article for Orthopedic Design & Technology, Keith Glaser, Director of Medical & Hygiene at YKK USA, explains how choosing the right supply partner can help medical device manufacturers optimize TCO.

Partnering for Innovation

With their unique perspective and capabilities, suppliers are ideal resources to help medical device manufacturers innovate, drive competitiveness, and enhance profitability. But innovation can go even further when manufacturers align themselves with suppliers that bring a new level of insight that can only result from the formation of trusting, intimate relationships with their customers.

Develop Winning Medical Devices with Early Supplier Engagement

To stay competitive in a crowded and ever-evolving industry, medical device manufacturers must consistently deliver value in two ways: through innovative products that improve safety and efficacy for the patient and by maximizing cost-effectiveness throughout the product life cycle from development and launch through scale-up and mass production.

How to Design Medical Devices with Sustainability in Mind

Sustainability has risen to the top of the corporate agenda in many industries, including the medical device market.

FAQs

What kind of fabricated items can YKK offer?

YKK can supply standard cut, custom shape die cuts, kiss cuts, adhesive coins, and complete product assemblies including packaging.

What type of adhesives does YKK have?

YKK offers rubber based, acrylic based, and weldable polyurethane based adhesive.

What other features are available in YKK's Powerhook Products?

YKK offers a unique, customized logo process to help our customers differentiate their products.

How can YKK control product quality?

YKK thinks quality first. “Insist on quality in everything” is one of YKK’s core values. YKK facilities are TS16949 and ISO9001 registered.