SUMMARY

This article explores the best way to sew extruded plastic hook fasteners in order to prevent tears. Considerations include sewing thread and stitch length as well needle size.

POWERHOOK® FASTENER SELECTION

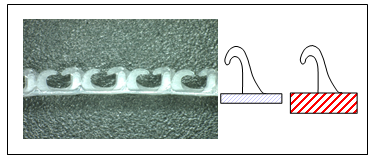

POWERHOOK® fasteners are molded hooks produced with extrusion technology. They vary in material polymer and performance, and can be manipulated by hook shape, size, and density per square inch to suit the customer’s needs. POWERHOOK® fasteners required in a sewing or stapling application is extruded with a thicker base to endure the stress when punctured or perforated by the sewing needle or staples.

SEWING THREAD AND STITCH LENGTH

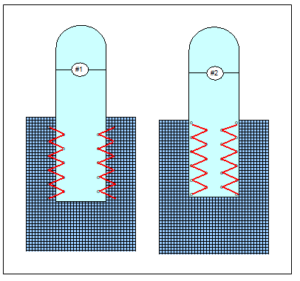

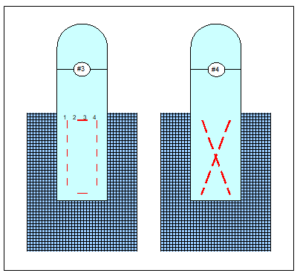

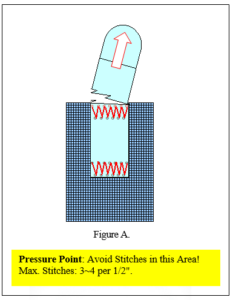

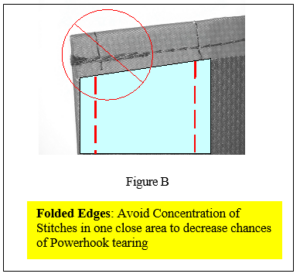

Tearing can be avoided if the needle and thread used are as small as possible yet still able to penetrate the substrate material and maintain the desired holding strength for the application. In general, the minimum holding strength of the sewing thread should always be adequate for the customer’s application and greater than the shear strength of the POWERHOOK® fasteners. To maintain a minimum strength above the shear force of the POWERHOOK® fasteners, thread sizes in the range of 300-450 denier with a stitch density of 6-8 stitches per inch should be adequate. A relatively long stitch is recommended for these plastic structures since they are susceptible to ripping, and longer stitch length reduces this risk by making fewer needle holes.

Recommended Stitching

Stitching Mistakes

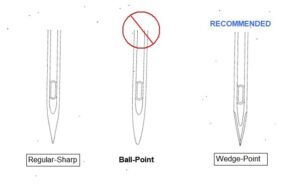

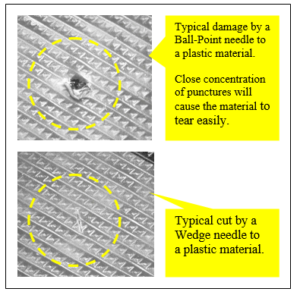

RECOMMENDED SEWING NEEDLE

Machine needles are made in different sizes and types to suit varying sewing needs. Needle sizes range from fine (#9) for lightweight fabrics to heavy (#18) for very heavy ones. Sizes 11 and 14 are used most often for general sewing. A second consideration is the type of point. Regular, sharp-pointed needles are used for most sewing. A ball-point needle for knits is not recommended since its rounded point is designed for sliding between the yarns rather than piercing them. YKK recommends the wedge-point needle, designed for use on leather and vinyl, which easily pierces these fabrics to make a hole that closes back upon itself. This reduces the risk of stitches tearing the plastic.

Visit our website to see YKK’s full line of hook and loop products or contact us to learn more.

POWERHOOK is a registered trademark of YKK CORPORATION.

©2022 YKK Corporation of America