Ever since its founding, quality has been central to the YKK Group’s management, and all of its business activities therefore revolve around the assurance of quality. Maintaining stable and constant quality has become one of the key concerns for many global manufacturers, and in order to support these companies, YKK has established YKK Fastening Standards (YFS) to provide products of the same quality level, wherever and whenever they are manufactured. Each YKK production site conducts various quality tests and reports the results to our headquarters in Japan on a regular basis in order to maintain and assure a consistent quality level.

Quality

Seeking corporate value of higher significance

Quality is Central to the YKK Group’s Management and Business Activities

Quality Regulations and Standards

Consumer Products Safety Improvement Act of 2008 (CPSIA)

The CPSIA was signed into law by President Bush in August of 2008, amending the provisions of the Consumer Product Safety Act. The main objectives of the CPSIA were to (a) strengthen consumer product safety standards, (b) increase safety requirements for chindren’s products and (c) revitalize the Consumer Product Safety Commission. YKK does not make consumer products, howevber, its components are used in consumer products. Major requirements of the CPSIA impacting our customer’ products and YKK’s commitment are as follows:

Lead content in surface coating in substrates

Lead content in products manufactured by YKK, except TZN airtight/watertight zippers and zippers with lead crystals/rhinestones, does not exceed the lead content requirements of the CPSIA, as confirmed through internal testing.

Phthalates

Products, manufactured by YKK, except TZN airtight/watertight fasteners and Rail Seal Fasteners with PVC materials, do not exceed CPSIA phthalate limitations, as confirmed through internal testing.

Japanese Law 112

Japanese Law 112 is an act to regulate household products that contain harmful substances. A major requirement of the law that relates to fastening products is the regulation of formaldehyde (JIS L 1041/Japanese Law 112).

YKK® zippers meet the most stringent formaldehyde requirement of the above mentioned law.

Soluble Elements Restriction per the Consumer Safety Specification for Toy Safety (ASTM F963)

The purpose of this specification is to establish safety requirements for toy safety in the US. A key provision of this is the restriction of soluble migrated elements (antimony, arsenic, barium, cadmium, chromium, lead, mercury, selenium) content in paint or paint similar surface coating (ASTM F963-08 4.3.5.2). As determined through internal testing, YKK’s products meet this standard.

REACH

REACH is the European Community Regulation on chemicals and their safe use, which deals with registration, evaluation, authorization and restriction of chemical substances. Major requirements of the law that could be related to fastening products are listed below:

- SVHC (substances of Very High Concern) – None of the 46 substances listed in the candidate list of SVHC (as of March 1st, 2011) are found in YKK’s major products in a concentration more than 0.1% (w/w), except Rail Seal Fasteners with PVC materials and TZN airtight/watertight zippers.

- European Nickel Restriction (part of Annex XVII) – All YKK® products indicated as “N-ANTI” meet the above mentioned nickel restriction. Metal zippers using nickel material, such as 3YN, 3MN, 4MN, 5RN, 5RNM etc., metal finishes using nickel material, such as NP, NS, HP etc. do not meet this regulation.

- European Azo colorants and Azo dyes Restriction (part of Annex XVII) – YKK® products meet the Azo colorants and Azo dye restrictions.

YKK Group Quality Pledge

Ever since founding quality has been central to the YKK Group’s management and all business activities resolve around the assurance of quality.

We value the bond of “trust” with our customers and provide our products and services with insistence on quality.

Bond of "trust" with customers

We will collaborate with our trading partners to deliver products and services that will truly satisfy customers and society. We will do so by taking seriously the opinions of our customers and being sensitive to the needs of society and markets, not only in relation to our products but in all aspects including sales and after — sales services.

Insistence on quality

We will insist on pursuing the highest quality expected by customers in our products and realize globally consistent quality based on the concept of integrated production.

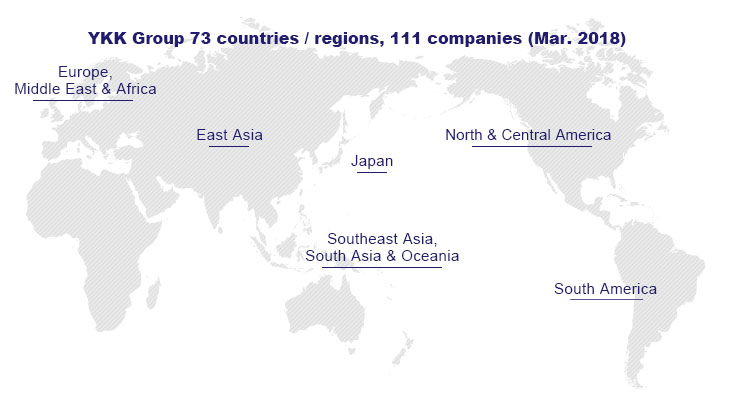

Quality Management: YKK Worldwide Network

Many manufacturers are now producing in multiple locations around the world as the globalization of manufacturing continues to expand.

YKK also abides by laws and regulations around the world concerning safety, environmental, and social issues to meet customer requests from various regions. We have been reinforcing our quality management system, and in some cases, have developed specific products to meet certain laws and regulations.

Laws and Regulations

YKK has always made safety and quality our top priorities and has thus been investing its resources to ensure that products manufactured by YKK meet all applicable standards. Below are descriptions of some of those key laws.

United States

Consumer Products Safety Improvement Act of 2008 (CPSIA)

The CPSIA was signed into law in August 2008, amending the provisions of the Consumer Product Safety Act. The main objectives of the CPSIA are to (a) strengthen consumer product safety standards, (b) increase safety requirements for children’s products and (c) revitalize the Consumer Product Safety Commission. YKK does not make consumer products. However, its components are used in consumer products. Major requirements of the CPSIA impacting our customers’ products and YKK’s commitments are described below:

Lead content in surface coating and substrates

Lead content in products manufactured by YKK, except PROSEAL® airtight/watertight zippers and zippers with lead crystals/rhinestones, does not exceed the lead content requirements of the CPSIA, as confirmed through internal testing.

Phthalates

Products manufactured by YKK, except PROSEAL® airtight/watertight fasteners and Rail Seal Fasteners with PVC materials, do not exceed CPSIA phthalate limitations, as confirmed through internal testing.

EU

REACH

Regulation (EC) No 1907/2006 of the European Parliament and of the Council on the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) is the European Community Regulation of the safe use of chemicals and deals with registration, evaluation, authorization and restriction of chemical substances. Major requirements of the law that can potentially be related to fastening products are listed below:

SVHC (Substances of Very High Concern)

None of the 174 substances listed in the candidate list of SVHC (as of July 2017) are found in YKK’s major products in a concentration of more than 0.1% (w/w), except Rail Seal Fasteners with PVC materials, PROSEAL® airtight/watertight zippers, and flame retardant zippers with Meta-Aramid tape.

European Nickel Restriction (part of Annex XVII)

All YKK® products indicated as “N-ANTI” meet the above mentioned nickel restriction: Metal zippers using nickel material, such as 3YN, 3MN, 4MN, 5RN, 5RNM etc., metal finishes using nickel material, such as NP, NS, HP etc.

European Azo colorants and Azo dyes Restriction (part of Annex XVII)

YKK® products meet Azo colorants and Azo dyes restrictions.

Product Testing Methods

Learn about our product testing methods.