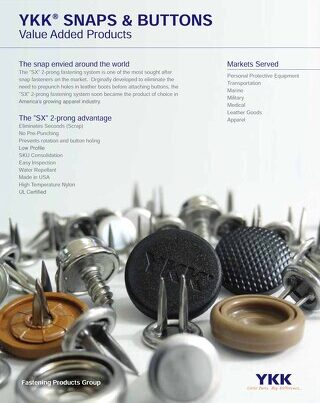

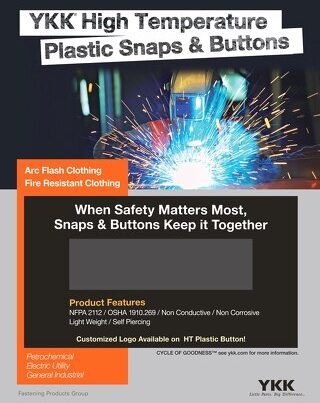

YKK Americas Group manufactures heat and fire resistant zippers, snaps, and other closures for FR Workwear garments. From oil rigs to electrical power plants, our fasteners are designed to function under the most demanding conditions and harsh environments. Our products are certified by UL to meet the requirements of NFPA 2112 Standard on Flame-Resistant Garments for Protection of Industrial Personnel Against Flash Fire.

FR Workwear

Designed for demanding conditions and harsh environments

FR Workwear Market: Regulations

For more information on YKK and FR workwear market regulations, click here.

FR Workwear Catalogs

FAQs

What is the difference between Flame Resistant and Flame Retardant products?

Flame Resistant products resist burning or ignition when exposed to a flame (YKK® zippers using Meta-Aramid tape). Flame Retardant (FR) products are slow burning when exposed to a flame and may self-extinguish when a flame is removed (FR treated polyester zippers and FR treated nylon hook & loop)

Do your products meet NFPA regulations?

Yes, our zippers using Meta-Aramid tape, high temperature plastic snaps & buttons, and high temperature plastic parts meet the thermal and design requirements in NFPA 2112. YKK uses UL as our third party certification lab.

Are your zippers Arc Flash rated?

Our zippers using Meta-Aramid tape, high temperature plastic snaps & buttons, and high temperature plastic parts are certified to meet the performance criteria in NFPA 2112 by UL. There is no individual component test for Arc Flash, the level of the Hazard Risk Category (HRC) is determined by the garment design. In order to meet the garment requirements in ASTM F1506, any metal parts (metal zippers, button rivets and burrs) must not cause harm to the user, and they are typically covered to prevent thermal conduction to the user’s skin.