The YKK Group works to maintain manufacturing and product safety through proper understanding and management of chemical substances. Further, we endeavor to minimize environmental impacts by reducing our usage of chemical substances.

Chemical Management

YKK's socially responsible solutions for hazardous waste disposal

Reducing Chemical Substances

We comply with laws and agreements and also take action to mitigate environmental risks, such as by preserving soil, ground water, air, and water.

Additionally, we are taking steps to prevent environmental accidents before they occur. Being on of its most important environmental liabilities, the YKK Group properly manages and disposes of fluorocarbons, asbestos, soil pollutants and PCBs.

Initiatives to Tackle Ozone Depletion and Global Climate Change

The YKK Group has established guidelines stipulating renewal deadlines for specific fluorocarbons (such as CFC and HCFC) among products that use fluorocarbons. Fluorocarbons contain substances that can destroy the ozone layer and therefore have a major negative impact on our atmosphere. The entire YKK Group will continue to work toward reducing emissions of fluorocarbons while also systematically renewing equipment.

Domestic PCB Disposal

In 2008 we began disposal of appliances containing a high concentration of PCBs (polychlorinated biphenyls) and in FY2016, we completed the disposal of 667 appliances. We also completed the disposal of waste electrical equipment that had been in storage and contained minute amounts of PCBs.

Overseas Environmental Liabilities

The YKK Group confirms that there is no link to our activities and health problems as we strive to understand our environmental liabilities in overseas locations. We promote disposal that takes each country’s circumstances into account and conduct proper storage and disposal in every location.

New Technologies for Eliminating the Use of Harmful Substances

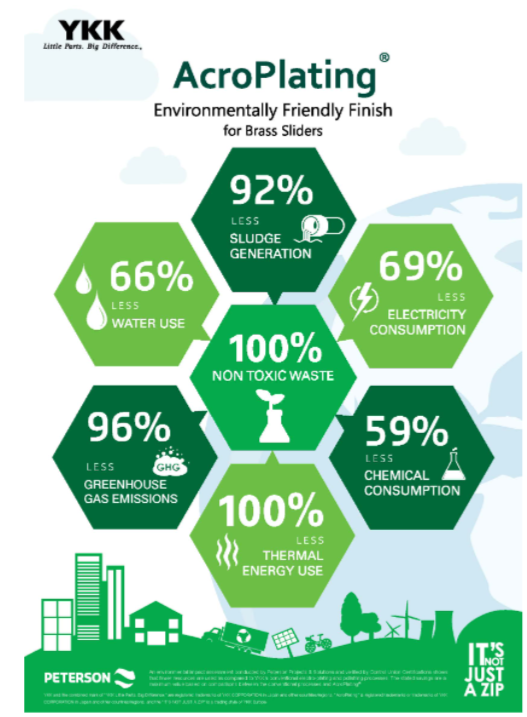

AcroPlating®

Conventional electroplating involves the use of large amounts of water and electricity as well as small amounts of certain harmful substances. YKK has been working for many years to reduce or eliminate harmful chemicals from the manufacturing process.

YKK’s new AcroPlating® technology completely eliminates the use of harmful substances such as cyanide, chromium, and selenium from the plating process. Additionally, AcroPlating® technology has been shown to reduce GHG emissions by 96%, water usage by 66%, and electricity consumption by 69% in the manufacturing of finishes for brass sliders. At YKK, all harmful substances and wastewater used or generated during plating operations are processed and disposed of in accordance with applicable environmental and other laws and regulations.

Development of New Paints

We completed development of a paint with reduced toluene and xylene that is safer for people and the environment. We began the process of switching over to this new paint in FY2021.

Maintaining and Improving Environmental Compliance

Deployment of the Higg FEM in plants

YKK is a member of the Sustainable Apparel Coalition (SAC), an international sustainability organization for the apparel industry. We have implemented the Higg Facility Environmental Module (Higg FEM), an industry standard environmental impact assessment tool developed by SAC, in 23 plants around the world. Our use of Higg FEM confirms our compliance with global standard environmental commitments and we continue to share these commitments with our business partners.

View our Higg FEM scores.

The Higg FEM assesses:

- Environmental Management Systems

- Energy Use and Greenhouse Gas Emissions

- Water Use

- Wastewater

- Emissions to Air (if applicable)

- Waste Management

- Chemical Management

In-house Trainings for International Manufacturing Plants

To disseminate industry standards and those of YKK throughout the Group, we hold in-house trainings for international manufacturing plants. Expert subcommittees and regional headquarters work together to implement trainings with a focus on water discharge, air emissions, and chemical management. In addition to complying with the laws and regulations of each country and region we operate in, we are working on the lateral deployment of appropriate environmental management expected on a global level.

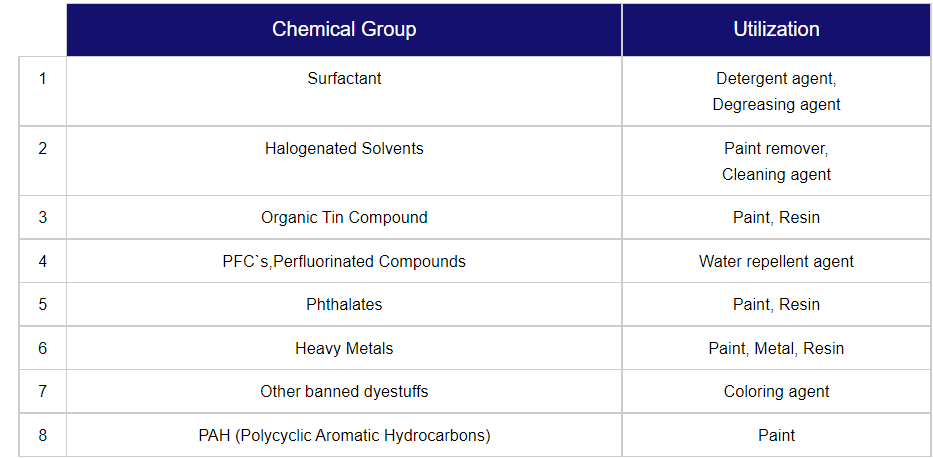

YKK Restricted Substance List

In recent years, the impact of chemicals used in the supply chain on human health and the environment is gaining greater attention. In response to the danger of such chemicals, we continue to find ways to minimize the environmental impact of those used in the fastening industry. YKK is working to manage our use of chemicals throughout the manufacturing process in accordance with internal standards (YKK RSL), which were created based on the Manufacturing Restricted Substances List (MRSL) of Zero Discharge of Hazardous Chemicals (ZDHC) and industry standards such as those of OEKO-TEX.

Supplier Surveys Based on the YKK RSL

In addition to issuing the 2020 version of the YKK RSL and disseminating it to the 44 companies that manufacture our fastening products, we are currently collecting responses regarding compliance status from 792 suppliers and conducting ongoing surveys.