One of the most common misunderstandings regarding YKK® water protective zipper product offerings is the difference between water-resistant and waterproof. These are often used interchangeably in conversation by both our customers and the industry in general. It is not until you understand YKK’s water protective product offerings that you begin to realize the extreme differences in these terms.

YKK offers the following categories of products that can be used to protect the user from increasing water exposures.

Standard water-resistant zippers

Standard water-resistant items are coil and VISLON® zippers with a DWR (Durable Water Repellent) coating applied during the dyeing process. This style zipper is designed to repel water by decreasing the surface tension of the zipper tape. When exposed to water, this zipper will allow the water to bead up on the surface of the textile tape. This prevents the water from penetrating the surface of the zipper tape, keeping the user dry. These zippers look no different from the standard coil and VISLON® zippers pictured below until exposed to water.

YKK’s AquaGuard® water-resistant zippers

YKK’s AquaGuard® zippers are also considered water-resistant but have an added layer of protection from the elements. These zippers use a water-repellent polyurethane film coating on one side to help shed water away from the zipper and enhance the appearance of garments. The other side is spray-coated with a DWR for increased surface tension and improved prevention of water penetration. These zippers can be RF welded or ultrasonically bonded or sewn to PU-coated materials or fabric. These types of zippers are available in both T4 (Shiny) and T5 (Matte) Coil and VISLON® zipper versions as pictured here:

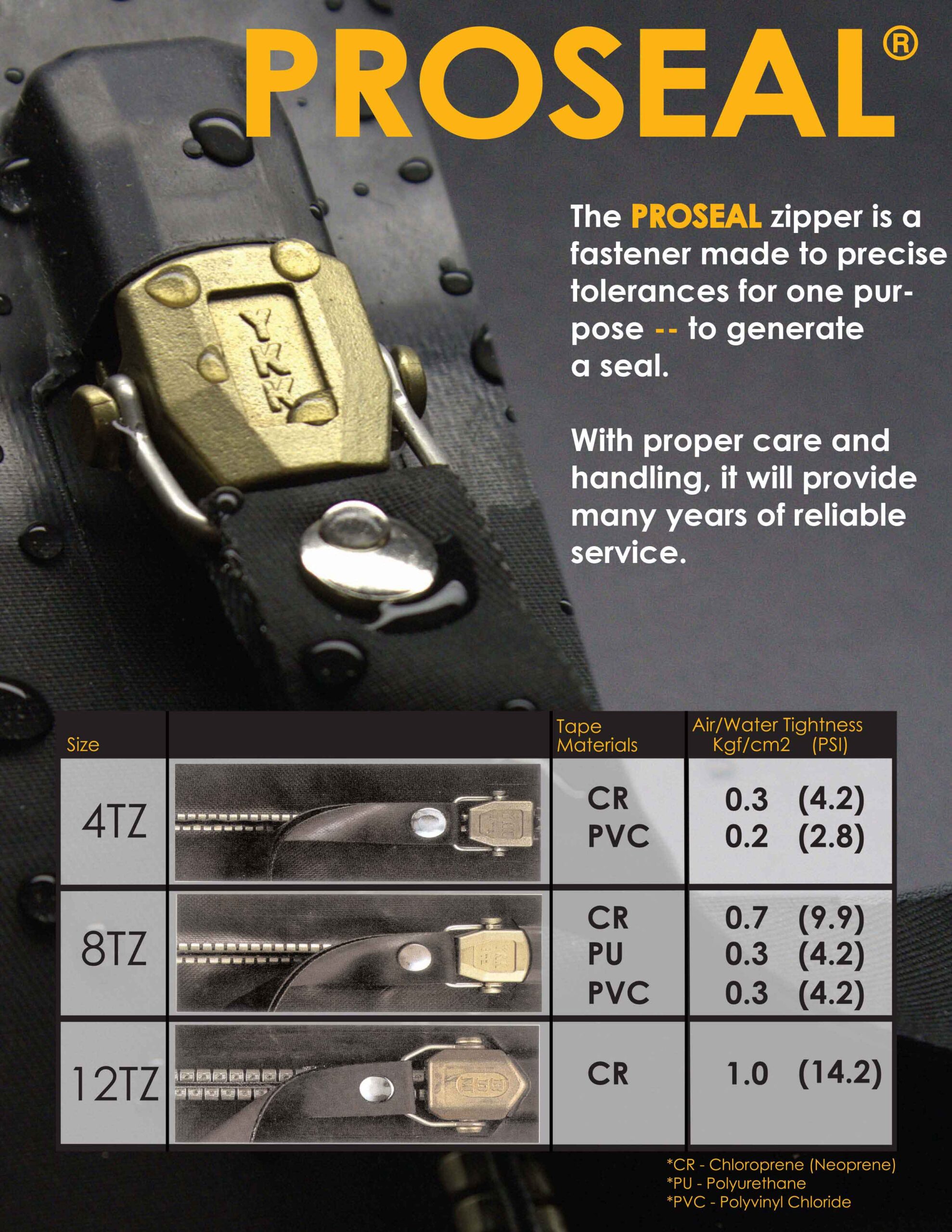

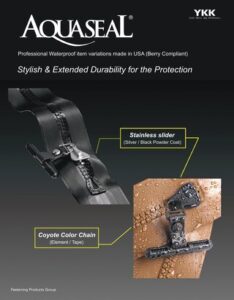

YKK’s airtight / watertight / waterproof zippers

YKK’s airtight / watertight / waterproof products make up several styles of zippers that provide our customer’s slider fasteners that offer a completely waterproof design with differing levels of airtightness. These zippers are designed to 100% prevent water from penetrating the exposed surface of the zipper. Our AQUASEAL® zipper combines the technology used in VISLON® zippers with an innovative seal between the elements allowing for a highly flexible and easy operation with perfect protection for the elements above or below the water. YKK’s PROSEAL® zipper uses metal zipper technology to produce a pressure-tight zipper that can withstand the requirements of commercial diving or hazardous chemical applications. These zippers can be RF welded, ultrasonically bonded, or sewn/seam-sealed into the customer application. AQUASEAL® zipper is only offered with polyurethane tape, and PROSEAL® zipper is being provided in polyurethane, PVC, and chloroprene rubber zipper tapes. These waterproof zippers are 100% pressure tested during the production process, ensuring that each zipper arrives fully capable of functioning to the prospective pressure specifications. Both the AQUASEAL® and PROSEAL® zippers are pictured here.

YKK, VISLON, AQUAGUARD, PROSEAL are registered trademarks of YKK CORPORATION in Japan and other countries and regions.